What is Plywood?

Plywood is an engineered wood product made by bonding thin wood veneers (called plies) with adhesive under heat and pressure. These layers are stacked in alternating grain directions (90° angles) to enhance strength, prevent warping, and resist cracking.

Why Choose Plywood?

✔ More stable than solid wood (resists shrinking/swelling)

✔ Stronger than MDF or particleboard

✔ Cost-effective for construction and furniture

✔ Versatile – available in waterproof, flexible, and fire-resistant variants

17 Types of Plywood & Their Uses

1. Softwood Plywood

-

Material: Cedar, pine, redwood

-

Uses: Roof sheathing, subfloors, sheds, dog houses

-

Pros: Affordable, lightweight

-

Cons: Not moisture-resistant

2. Hardwood Plywood

-

Material: Oak, walnut, birch, maple (7+ layers)

-

Uses: Furniture, cabinets, musical instruments

-

Pros: Extremely durable, aesthetic grain

-

Cons: Expensive

3. Marine Plywood (BWP – Boiling Water Proof)

-

Material: Fir or larch (no knot holes)

-

Uses: Boats, bathrooms, coastal structures

-

Pros: Waterproof glue, warp-resistant

-

Cons: Needs sealing to prevent rot

4. Exterior Plywood

-

Material: Oak (best for mold resistance)

-

Uses: Outdoor furniture, decks, siding

-

Pros: Weatherproof adhesive

-

Cons: Not fully waterproof (unlike marine ply)

5. Aircraft Plywood

-

Material: Birch, mahogany (thin, high-strength veneers)

-

Uses: Aircraft, boats, high-load furniture

-

Pros: Lightweight, industrial-grade strength

-

Cons: Very expensive

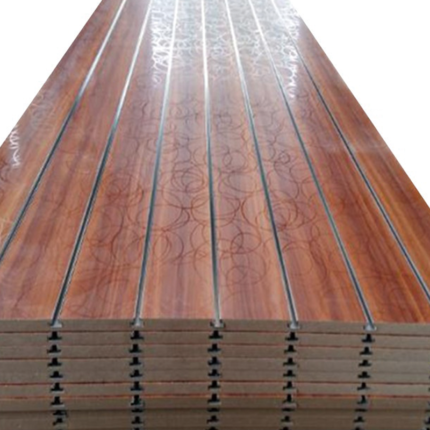

6. Flexible (Bendable) Plywood

-

Uses: Curved furniture, arches

-

Pros: Can bend without cracking

-

Cons: Weak for structural use

(Continue with 7–17, summarizing key points concisely…)

Plywood Grades Explained

Plywood is graded from A (highest) to D (lowest) based on surface quality:

-

A-A: Flawless both sides (e.g., marine ply)

-

A-B: Premium front, minor defects on back

-

C-D: Knots/gaps (suitable for structural layers)

-

X Grade: Exterior-rated (waterproof glue)

Pro Tip: Use A-grade for visible surfaces, C/D for hidden framing.

Plywood Sizes & Thickness

| Common Sizes | Thickness | Best For |

|---|---|---|

| 4×8 ft | 1/8″–1/4″ | Cabinets, crafts |

| 4×9 ft | 1/2″–3/4″ | Furniture, subfloors |

| 5×5 ft | 1″–1.5″ | Roofing, heavy-duty use |

Note: Thinner plywood bends easier; thicker plywood handles heavier loads.

Plywood vs. MDF vs. Particleboard

| Feature | Plywood | MDF | Particleboard |

|---|---|---|---|

| Strength | High | Medium | Low |

| Moisture Resistance | Good (if BWR/BWP) | Poor | Very Poor |

| Cost (4×8 sheet) | $30–$150 | $25–$60 | $15–$40 |

| Best For | Furniture, roofing | Painted cabinets | Budget temporary builds |

How to Choose the Right Plywood

-

For Moist Areas: Marine or BWR plywood

-

For Budget Furniture: MR-grade softwood

-

For Outdoor Use: Exterior-grade (ACX) or OSB

-

For High Loads: Hardwood or aircraft plywood

Avoid: Warped boards, visible edge gaps, or low-grade ply for critical structures.

FAQs

Q: What’s the strongest plywood?

A: Marine plywood (A-A grade) – waterproof and warp-resistant.

Q: Is MDF stronger than plywood?

A: No – plywood has higher shear strength, but MDF is denser and smoother for painting.

Q: Which plywood is cheapest?

A: CDX (construction-grade) or particleboard.

Q: Best plywood for kitchen cabinets?

A: BWR or marine plywood (moisture-resistant).

Conclusion

Plywood’s versatility, strength, and affordability make it ideal for everything from DIY furniture to industrial construction. Match the type (marine, hardwood, etc.) and grade (A-D) to your project’s needs, and always prioritize waterproof adhesives for wet areas.

Need help selecting plywood? Comment below with your project details!

Recent Comments