Your Trusted OEM/ODM Partner

Contact an Agent!

Call: +370 693 79160

Email: info@uabirmarimwood.com

Visit: Europos tarybos g. Kalviškės,

Vilniaus r. sav., Lithuania

Why Choose Our OEM/ODM Services?

✔ End-to-End Customization – From concept to mass production

✔ In-House R&D & Design – 12+ engineers dedicated to innovation

✔ Large Production Capacity – 70,000 CBM/month (plywood, OSB, MDF)

✔ Strict Quality Control – ISO 9001, CE, FSC, PEFC, JAS-ANZ certified

✔ Global Logistics Support – Smooth customs clearance & on-time delivery

Quality Assurance – Built into Every Step

✅ Raw Material Inspection – Only premium wood sources

✅ In-Process QC – Monitoring during production

✅ Pre-Shipment Inspection – Ensures compliance with your specs

✅ Certifications – ISO 9001, FSC, CE, PEFC, JAS-ANZ

Production Capacity & Facilities

-

Own Factories – Plywood, OSB, MDF, LVL, tooling

-

Monthly Output – 70,000+ CBM

-

Advanced Machinery – CNC cutting, precision lamination, automated presses

Our OEM/ODM Capabilities

Custom Product Development

-

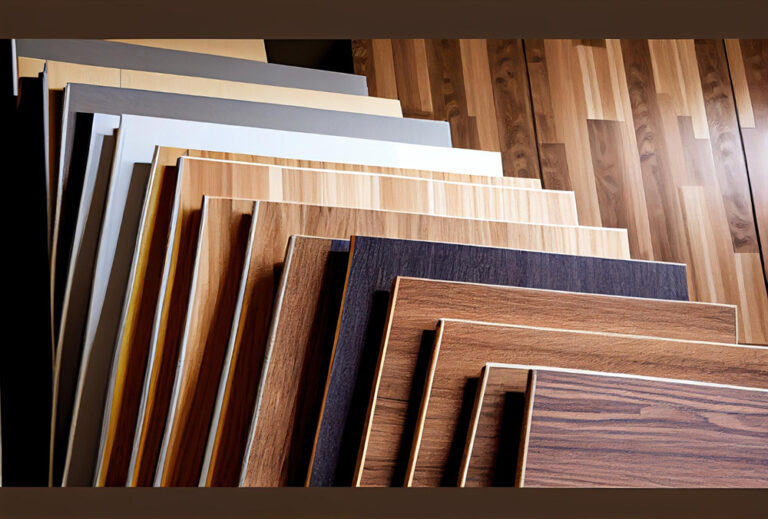

Material Selection – Hardwood, softwood, fire-retardant, moisture-resistant

-

Size & Thickness – Tailored to your specifications

-

Surface Finishes – Melamine, veneer, laminate, pre-painted options

-

Branding & Packaging – Private labeling, custom logos, retail-ready packaging

Industries We Serve

-

Furniture Manufacturing (Plywood for cabinets, tables, beds)

-

Construction & Interior Design (OSB, MDF for walls, flooring, ceilings)

-

Retail & Supermarkets (Custom display boards, shelving)

-

Industrial Applications (LVL for beams, structural support)

Requirement Analysis

-

We assess your needs (market use, design preferences, budget).

-

For abstract concepts, our engineering & marketing teams provide expert guidance.

Technical Review

- Feasibility check with suppliers.

-

-

Cost-effective material & production planning.

-

Cost & Schedule Proposal

-

Transparent pricing & production timeline.

-

Contract signing.

Sample Development

- Prototype testing (boiling, strength, durability).

-

-

Client feedback & refinements.

-

Trial Production

-

Small-batch test run to ensure consistency.

-

Risk assessment before mass production.

Mass Production & Delivery

- Full-scale manufacturing with strict QC checks.

-

-

Logistics coordination for timely shipments.

-